Dry Ice Blasting Applications

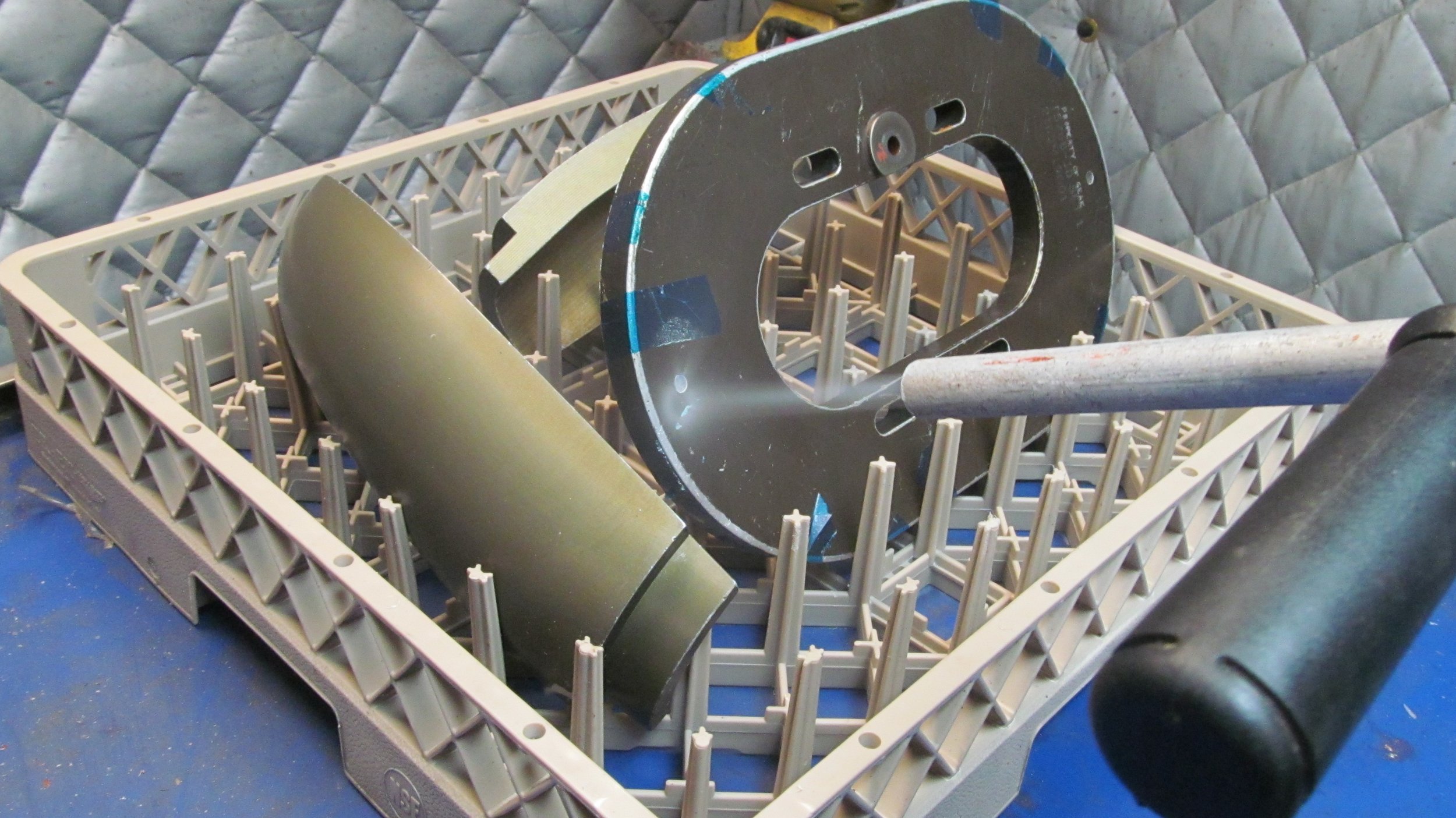

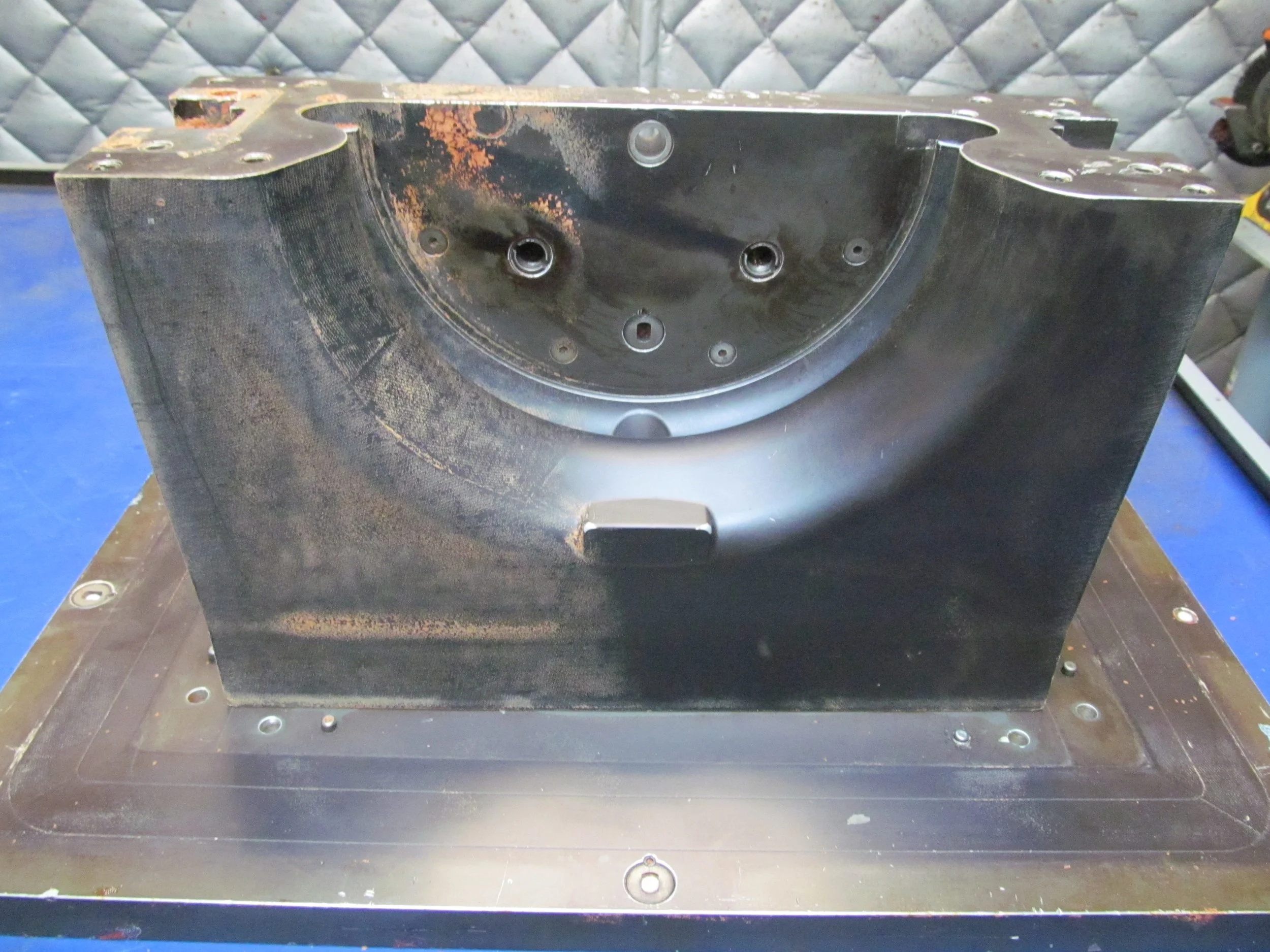

Composite Tool Cleaning

Meet stringent industry demands with a composite tool cleaning solution that is fast, delicate and does not use solvents. Dry ice cleaning safely removes a variety of residual process contaminants from composite molds and tooling without damage.

Benefits

Environmentally sustainable

Clean in-place and online

Reduce Production Downtime

Non-abrasive

Eliminate manual cleaning

Non-toxic and non-conductive

No secondary waste

Improve product quality and reduce scrap

Specific Use Cases

Resin transfer molding

Compression Molding

Extrusion

Aerospace & Aviation

Autoclave flooring walls

Mixing equipment

Wet-layup

Medical Device

Post-processing equipment

Highly polished tools

Related Industries

Teflon-coated tools

Plastics & Composites

Pre-pregging equipment

Why?

Dry ice blasting extends the life of composite molds and tooling by eliminating the need for harsh chemicals, wire brushes, and coarse pads. This non-abrasive process protects critical dimensions, parting lines, sealing surfaces, and preserves the mold surface finish, reducing wear over time.

Effectively clean composite tooling while safeguarding critical surface dimensions. Dry ice blasting cleans faster, more thoroughly, and with no residue, ensuring minimal downtime and optimal performance, which in turn guarantees the continued production of high-quality parts and a longer tool life.

Get in touch.

Have a project that needs powerful, eco-friendly cleaning here in Utah? Get in touch with IcePulse! Whether you have tough industrial buildup, delicate machinery, or need a non-abrasive cleaning solution, we’re here to help. Contact us today for a free consultation and see how dry ice blasting can save you time, money, and hassle.